جدول المحتويات

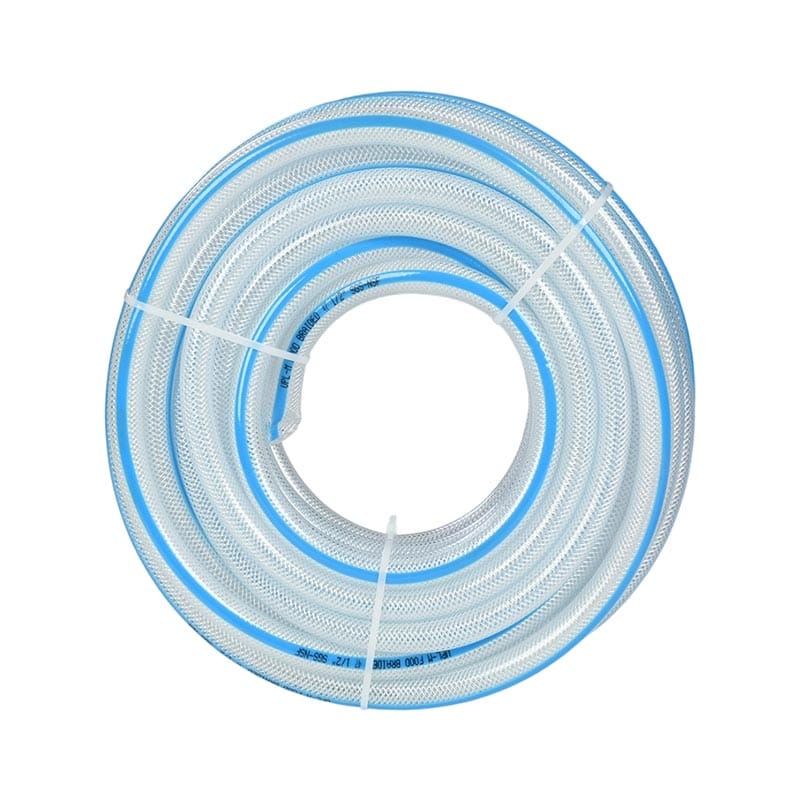

Clear fiber reinforced hose is widely used in industrial, agricultural, and commercial fluid transfer systems where visibility, flexibility, and pressure resistance are required at the same time. As a manufacturer specializing in reinforced PVC hose production, we often work with buyers who need a clear understanding of how this hose is constructed, how it performs under different conditions, and how to select the right specification for their application.

This article explains the structure, materials, manufacturing process, performance characteristics, and real-world applications of clear fiber reinforced hose, helping engineers, distributors, and procurement teams make informed decisions.

What Is a Clear Fiber Reinforced Hose?

A clear fiber reinforced hose is a type of transparent PVC hose that uses high-strength fiber yarn embedded between PVC layers to improve pressure resistance and structural stability. Unlike non-reinforced clear hoses, fiber reinforcement allows the hose to handle higher working pressure while maintaining flexibility and visual flow monitoring.

The transparent wall makes it easy to observe fluid movement, detect blockages, and identify contamination, which is why reinforced clear hoses are commonly used in water transfer, air supply, chemical conveying, and food-related applications.

Compared with standard PVC hose, a clear fiber reinforced hose offers:

- Higher pressure capacity

- Better dimensional stability

- Longer service life under continuous use

Materials Used in Clear Fiber Reinforced Hose Manufacturing

Material selection plays a critical role in hose performance. From a manufacturing standpoint, each component must be compatible in terms of flexibility, adhesion, and durability.

The inner tube is typically made from high-quality PVC compound, formulated to remain transparent while resisting cracking and deformation. The fiber layer uses polyester or similar high-tensile yarn, braided or spiraled to provide reinforcement without blocking visibility. The outer layer is another PVC coating that protects the fiber and improves abrasion resistance.

Balancing clarity, flexibility, and strength is one of the main challenges in producing reinforced transparent hose. Material formulation directly affects pressure rating, temperature resistance, and service life.

Manufacturing Process of Clear Fiber Reinforced Hose

As a clear fiber reinforced hose manufacturer, we follow a multi-stage production process designed to ensure consistent performance and dimensional accuracy.

First, the inner clear PVC tube is formed through precision extrusion. This layer determines the hose’s internal smoothness and flow characteristics. Next, fiber reinforcement is applied using a controlled braiding or winding process, ensuring uniform tension and coverage along the hose length. Finally, the outer PVC layer is extruded over the fiber to protect the reinforcement and provide structural integrity.

Throughout production, in-line inspection and pressure testing are used to verify wall thickness, diameter tolerance, and bonding strength between layers. This manufacturing approach ensures that each reinforced PVC hose meets the required working pressure and flexibility standards.

Key Technical Specifications and Performance Ratings

Clear fiber reinforced hose specifications vary depending on application requirements. Key performance indicators include working pressure, burst pressure, temperature range, and dimensional accuracy.

The table below shows typical technical parameters for reinforced clear PVC hose used in industrial applications:

| Parameter | Typical Range |

|---|---|

| القطر الداخلي | 6 mm – 50 mm |

| Working Pressure | 150 – 600 PSI |

| Burst Pressure | 3 × working pressure |

| نطاق درجة الحرارة | من -5 درجة مئوية إلى +65 درجة مئوية |

| Reinforcement Type | Polyester fiber braid |

| مادة | PVC (clear, reinforced) |

Actual pressure ratings depend on hose diameter, wall thickness, and fiber structure. For applications involving compressed air or continuous fluid transfer, selecting the correct pressure margin is essential.

Clear Fiber Reinforced Hose Applications Across Industries

Because of its versatility, fiber reinforced hose is used in many industries that require reliable fluid transfer with visual monitoring.

In industrial environments, it is commonly applied in air compressors, pneumatic systems, and machinery cooling lines. In agriculture, reinforced transparent hose is used for irrigation, spraying, and water distribution due to its flexibility and ease of inspection. Food and beverage processing facilities often select food-grade clear fiber reinforced hose to safely transport liquids while maintaining hygiene visibility.

Chemical transfer applications may also use reinforced PVC hose, provided material compatibility and temperature limits are carefully evaluated.

Advantages of Clear Fiber Reinforced Hose Over Other Hose Types

When compared with non-reinforced PVC hose, clear hose offers significantly higher pressure resistance and reduced expansion under load. This makes it suitable for applications where pressure fluctuations are common.

Compared with rubber hose, reinforced clear PVC hose is lighter, easier to handle, and allows real-time flow observation. The transparency reduces maintenance time by enabling quick visual inspection without system disassembly.

These advantages make reinforced clear hose an efficient solution for users who need strength without sacrificing flexibility or visibility.

How to Choose the Right Clear Fiber Reinforced Hose

Selecting the right hose begins with understanding operating conditions. Inner diameter should match system flow requirements, while working pressure must exceed the maximum operating pressure with an adequate safety margin.

Temperature exposure, chemical compatibility, and installation environment should also be considered. For specialized applications, custom clear fiber reinforced hose options such as modified wall thickness or specific fiber patterns may be required.

From a manufacturer’s perspective, clear communication of application details helps ensure the hose design matches real-world use conditions.

Customization Options and OEM Capabilities

Many industrial buyers require hoses tailored to specific systems. As an OEM reinforced hose supplier, we provide customization options including size variations, fiber reinforcement patterns, branding, and packaging.

Bulk orders and private-label production are available for distributors and equipment manufacturers who need consistent quality and long-term supply stability. Custom reinforced PVC hose solutions are particularly valuable for applications with non-standard pressure or installation requirements.

Quality Standards and Compliance Considerations

Quality control is essential for clear fiber reinforced hose used in demanding environments. Testing typically includes pressure testing, visual inspection, and dimensional verification.

For food and beverage applications, food-grade clear fiber reinforced hose is produced using non-toxic PVC compounds that meet applicable safety standards. Long-term durability testing helps ensure performance consistency throughout the hose’s service life.

خاتمة

Clear fiber reinforced hose combines transparency, flexibility, and pressure resistance, making it a practical solution for a wide range of industrial and commercial fluid transfer applications. Understanding its structure, materials, manufacturing process, and performance characteristics allows buyers to select the right hose with confidence.

From a manufacturing perspective, consistent material selection, precise reinforcement control, and thorough quality testing are key to delivering reliable reinforced PVC hose products. With the right specifications and supplier support, clear fiber reinforced hose can provide long-term performance and operational efficiency across multiple industries.

التعليمات

Q1: What is a clear fiber reinforced hose?

A: A clear fiber reinforced hose is a transparent PVC hose reinforced with high-strength fiber yarn, offering better pressure resistance and flexibility than non-reinforced clear hoses.

Q2: What are the main applications of clear fiber reinforced hose?

A: It is commonly used for water transfer, air compressors, industrial fluid conveying, agricultural irrigation, and food processing where visibility and durability are required.

Q3: How do I choose the right clear fiber reinforced hose?

A: Choose based on inner diameter, working pressure, temperature range, and chemical compatibility. For high-pressure or customized needs, select a reinforced PVC hose with appropriate fiber braid and wall thickness.

Q4: What is the difference between clear fiber reinforced hose and regular PVC hose?

A: The reinforced hose includes a fiber layer that increases pressure capacity and stability, while a regular PVC hose may expand under pressure and is less durable.

Q5: Can clear fiber reinforced hose be used for food and beverage applications?

A: Yes, food-grade clear fiber reinforced hose made with non-toxic PVC can be used in food and beverage processing, provided it meets the required safety standards and is properly maintained.